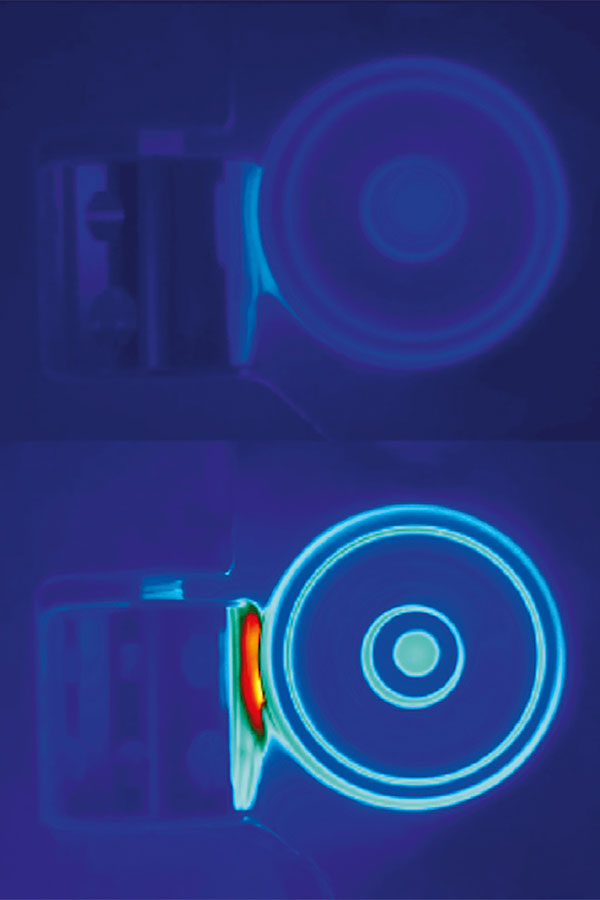

Additives are substances that are added to the base oil to reduce fric-tion and thus also wear on the tools. They consist of polar molecules and reactive compounds of phosphorus, sulphur, and chlorine, the last of which is increasingly frowned upon for environmental reasons. Using tribology experiments, i.e. friction tests, we investigate the effectiveness of additives in a laboratory setting. To visually demonstrate how additives affect the machining process, we took these thermal images using a thermal imaging camera. This is a simple friction test: The right cylinder rotates, while the left cylinder is pressed against it. In the lower set-up, a conventional mineral oil without additives is used as a coolant; in the one at the top, an oil with additives. This causes less friction at the point of contact – and thus less heat wear.

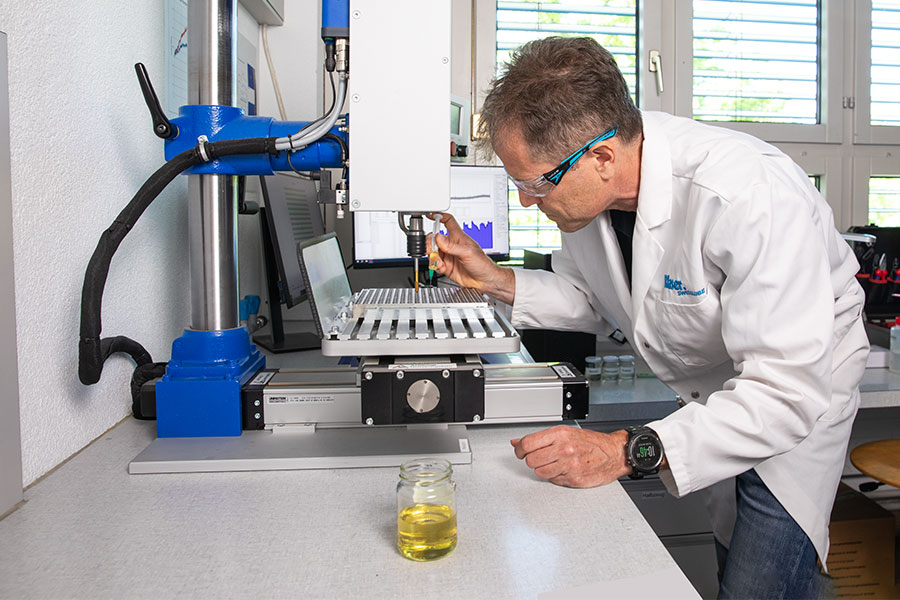

The so-called performance additives ensure that tools last longer (tool life). They also make it possible to machine more quickly at the same wear rate (material removal rate). Both make the process more productive. At Blaser, we analyze the im-pact of additives on the machining process and use these in various com-binations. Based on these results, we formulate products that are then tested for their practical suitability, first internally in our technology center and then in field tests. Knowing when to use which additives to achieve maximum results is immensely valuable for the machining industry.”

PhD in surface analysis of tribologically stressed surfaces