Text Thorsten Kaletsch

Titanium components are critical in the aerospace industry, but machining them presents significant challenges. Now, a close collaboration between a manufacturer of machining centers, a toolmaker, and a coolant specialist has led to remarkable improvements.

Three companies joined forces with precisely this goal in mind and achieved impressive results: the Japanese manufacturer of high-end machining centers, Makino, the German developer and manufacturer of high-quality precision and machining tools, Walter Tools, and Blaser Swisslube, the coolant experts from Switzerland. Their mission: process optimizations. The aim was to further reduce the time it takes to machine titanium components and to extend tool life.

Early 2021

The idea of a collaboration aimed at achieving process optimizations in titanium machining was born. During the international aerospace forum at Makino’s European headquarters, Andrea Biscardi, Product Manager for Makino Europe, and Daniel Schär, Senior Segment Manager for Aerospace and Medical at Blaser, defined the project framework and subsequently fired the starting gun.

At Blaser’s technology center in Hasle-Rüegsau, 27 metalworking fluids were tested – 22 of which had come from competitors, and 5 had been produced by Blaser Swisslube. The test also included a new formulation for titanium machining specifically for the aerospace industry. It had just been developed in the Blaser laboratory, which – with 70 employees – is one of the world’s largest in the coolant industry.

November 2021

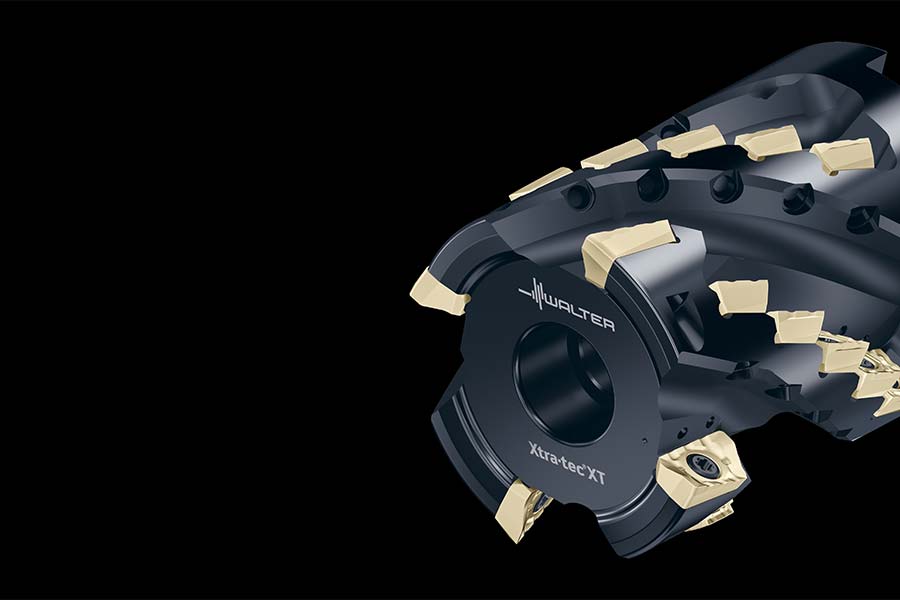

The initial tests were carried out in Kirchheim unter Teck (Germany), where Makino has its European headquarters. The T2 5-axis horizontal machining center in the company’s own technology center was made available for this purpose. This high-end machine had been developed specifically for milling titanium and titanium alloys. It is known for its good material removal rates in current aerospace applications. The Makino T2 features a rigid construction, an active damping system, and a high-performance spindle with coolant channel and high torque. At 70 bar and a 200 l/min flow rate, the high-pressure coolant system is very effective. However, without excellent tools, even the best machining center produces only standard results. Therefore, in this setting, a Walter porcupine milling cutter was used, which had been designed for roughing titanium components. It was still under development, so the intention was to optimize it as part of this project.

“THIS ENABLES US TO TEST AND FURTHER DEVELOP NEW TOOL CONCEPTS UNDER REAL-WORLD CONDITIONS.”

Dirk Masur, Industry Driver Aerospace at Walter Tools

The results in this setting were already promising. On the face insert, tool life with the widely used coolant was 27 minutes; with the newly developed Blaser product 31 minutes (plus 15 percent). On the peripheral inserts, the improvements were even more noticeable: 44 minutes with the standard product and 66 minutes with the new one (plus 50 percent).

January 2022

As part of the collaboration, Walter optimized the porcupine milling cutter. It now had a second, improved coolant channel in the front insert, which optimized the supply to the first row of inserts. As a result, the Blaser product was able to improve tool life to 42 minutes (another 35 percent increase).

November 2022

A further modification of the tool was tested. The indexable insert was now equipped with WaveCut. Walter had developed this new wave-shaped cutting-edge geometry specifically for demanding titanium applications. In addition, the manufacturer gave the insert a ceramic heat shield (CVD thin film). Impressive results were achieved in the same setting. The face insert’s service life was now 110 minutes – an increase of 307 percent when compared with the baseline in November 2021. For the peripheral inserts, a value of 105 minutes was measured. Compared to the baseline, this represented an increase of 138 percent.

A win-win situation

This example shows how machining titanium can be made considerably more cost-effective through professional collaboration. The commitment proved to be worthwhile for the companies involved. Dirk Masur, Industry Driver Aerospace at Walter, emphasizes the importance of collaborative projects like this one: “They enable us to test and further develop new tool concepts under real-world conditions.” The new M5250 porcupine cutter benefited greatly from this collaboration. Indeed, the M5250 developed as part of this partnership represents the latest generation of Walter’s indexable milling cutters. The rein-forced insert pockets and optimized insert seats – together with the newly developed WaveCut geometry and the separate cooling of each individual insert – result in a significantly longer tool life.

Blaser too gained valuable experience with its newly developed product Vasco Skytec H 600. “Following on from the standard tests and field tests for long-term stability, these application tests on the Makino T2 delivered meaningful comparative figures,” says Christoph Wüthrich, Application Engineer at Blaser Swisslube. “Compared to other coolants, tool life per cutting edge was 1.6 times longer with Vasco Skytec H 600, resulting in a massive increase in the material removal rate.”

Andrea Biscardi, Product Manager at Makino Europe, underlines the importance of the metalworking fluid in machining titanium: “The Makino T2 offers the perfect conditions for optimum high performance and precision cutting. In combination with the powerful coolant system, it achieves a good degree of cooling on the workpiece using conventional metalworking fluids. With Vasco Skytec H 600, you really do notice a clear difference.” Just as important, however, is the tool being used. If this is optimized for titanium, like the new M5250 porcupine milling cutter from Walter, “then impressive machine running times and outstanding cutting data can be achieved.”